Project C13 - 3D Printed Dielectric Structures for THz Applications

Principal Investigator: Prof. Dr. Niels Benson, UDE

Project C13 started in January 2019.

Achieved Results in the 1st Phase

Additive Manufacturing (AM) for signal processing applications is a scientifically hot topic for mm- and sub-mm wave applications, as the digital design freedom and flexibility of the AM technology provides solutions for implementation issues, associated with classical 2 and 2.5D manufacturing technologies. From a technological standpoint, these are mainly split block alignment issues for sub‑mm structures, as well as possible passive intermodulation products at interfaces due to design issues or interface oxidation.

Therefore, to address these limitations, the C13 project introduced a novel AM technology into the SFB MARIE, which is Lithography based Ceramic Manufacturing (LCM). This method has the potential for a structural resolution in the µm range, while allowing for a material density of above 99.5 %, an engineered / tailorable permittivity, as well as low loss tangents in the sub-mm wavelength range. Consequently, it was the objective of C13 to 1.) establish the LCM technology at the University of Duisburg-Essen, to 2.) investigate the technology limitations with respect to the parameters listed at the beginning of this paragraph and 3.) to enable first ceramic 3D-manufactured THz components.

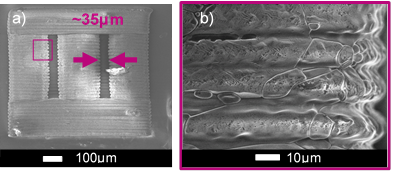

Fig. 1: Additive manufactured 3D- zirconia On-Chip resonator structure for 250 GHz operation, fulfilling the 1st phase C13 goals. a) SEM overview image demonstrating the 200 µm resonator diameter, as well as their 35 µm separation distance. b) resonator close-up view illustrating the current layer by layer roughness.

C13: In the 1st phase of MARIE, through a close collaboration with the C09, C05 and the M05 projects, the C13 project was able to successfully establish the LCM technology for the development of additive manufactured mm and sub-mm wave applications. Illustrated in Fig. 1 a) is a zirconia on-chip resonator structure for 230 GHz operation. The structure demonstrates the current feature size capability of the technology, allowing for structures, in this case a resonator diameter, with geometric dimensions in the 200 µm range and a feature spacing even down to the 35 µm range. Yet the image also demonstrates the need for further technology development. While the in-plane surface roughness is in the nm-range, the layer to layer roughness is limited to the µm range as indicated by the inset and Fig. 1b). To reduce this layer by layer artefact, and to enable feature sizes in the sub‑100 µm range, as close to the native resolution as possible, will be one task of the second funding period.

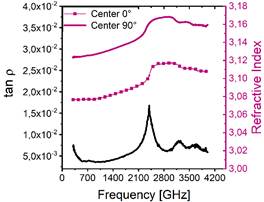

Illustrated in Fig. 2 is the result of a THz-Time Domain Spectroscopy (TDS) measurement in N2 atmosphere, showing the loss factor as well as the refractive index measured for an Al2O3 sample in the frequency range from 250 GHz to 4 THz. The measurement highlights the good suitability of the printed ceramic for THz applications with a low loss factor in the 10-3 range up to 2.1 THz. Beyond this frequency, the loss factor exhibits a type of resonance peak as well as an oscillation pushing the tan ρ into the 10‑2‑range (Fig. 2). This is interpreted to be the influence of changes in the extinction coefficient, which also leads to an increase in the refractive index in accordance with the Kramers-Kronig relation. The origin of this effect is currently under investigation. Interestingly, the printed alumina sample exhibits a birefringence effect, as demonstrated by the perpendicular 0° and 90° measurements, which is an indication for the crystallinity of the sample.

Fig. 2: Result of an orientation-dependent THz-Time Domain Spectroscopy (TDS) analysis for an 3D-printed alumina sample between 0.25 and 4 THz. Low loss THz properties are demonstrated, as well as an interesting birefringence effect.

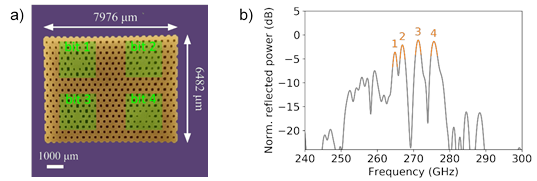

In conjunction with the C09 project, ceramic Photonic Crystal (PhC) structures were developed for 80 and 230 GHz (see e.g. Fig. 4), which show excellent respective loaded Q-factors of 490 and 380. Further, in contrast to the reference material High-Res Si, the alumina samples exhibited an excellent temperature stability during the measurement up to 120°C. Due to the high band gap of the alumina, a temperature stability of the high-Q behavior is expected up to temperatures of at least 400°C.

Fig. 3: LCM alumina 4-bit RRT at 230 GHz. a) Four resonators with different resonance frequencies are integrated in the PhC structure, demonstrating that PhC high-Q resonators can be manufactured at the targeted frequencies. b) Frequency response where each bit of information is determined by the presence or absence of a certain resonator, in this case 1111.

|

In the 2nd phase of MARIE C13 will be merged with C09.

Project-related publications

For all project-related publications please click here and scroll to the C13 section.